I've had a few people email me looking for some insight on setting up Syncro shifters. I don't claim to be all knowing on the subject, but I have had some success based on info I've read, as well as a couple of tricks I've picked up.

Syncro Syncro2

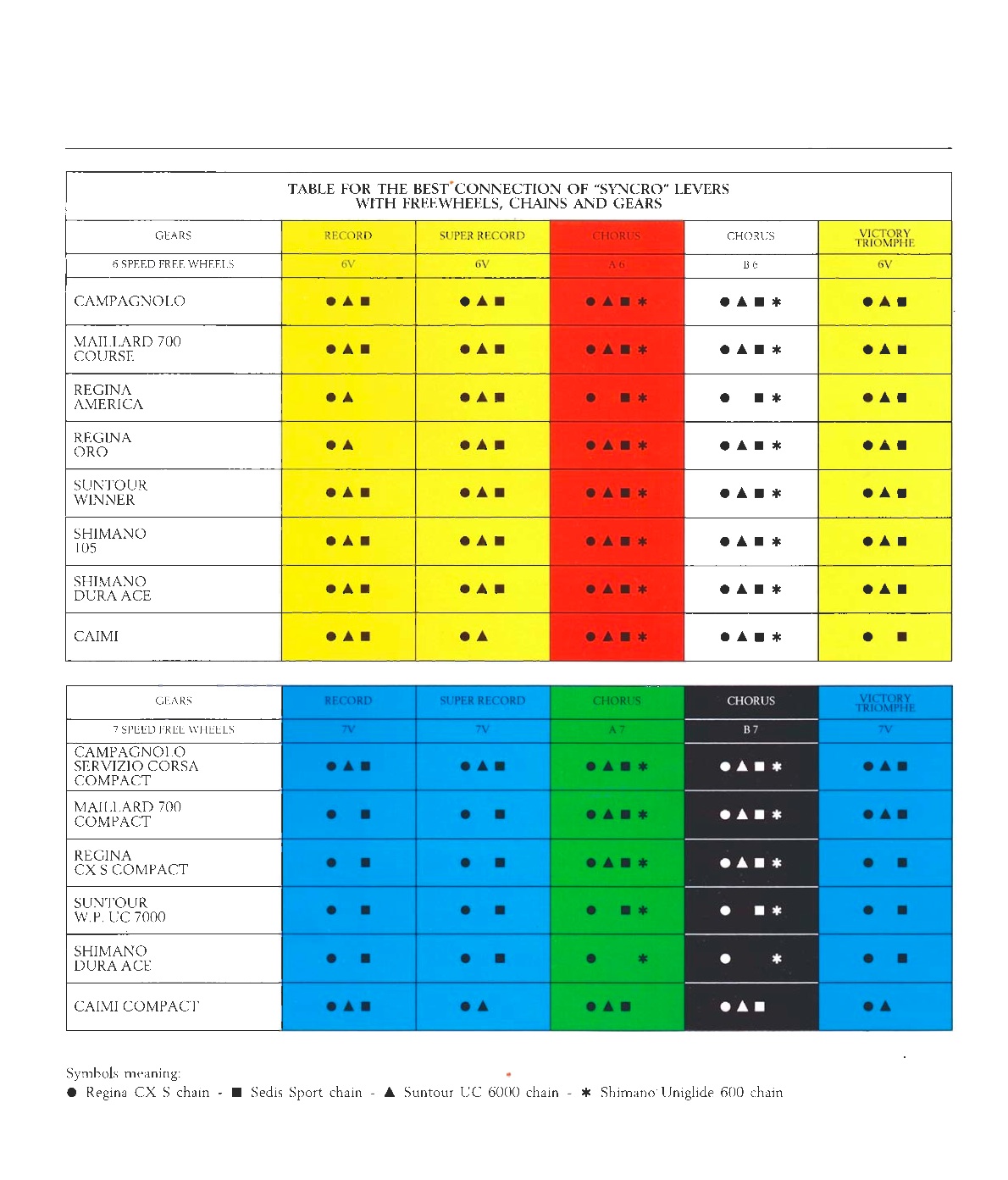

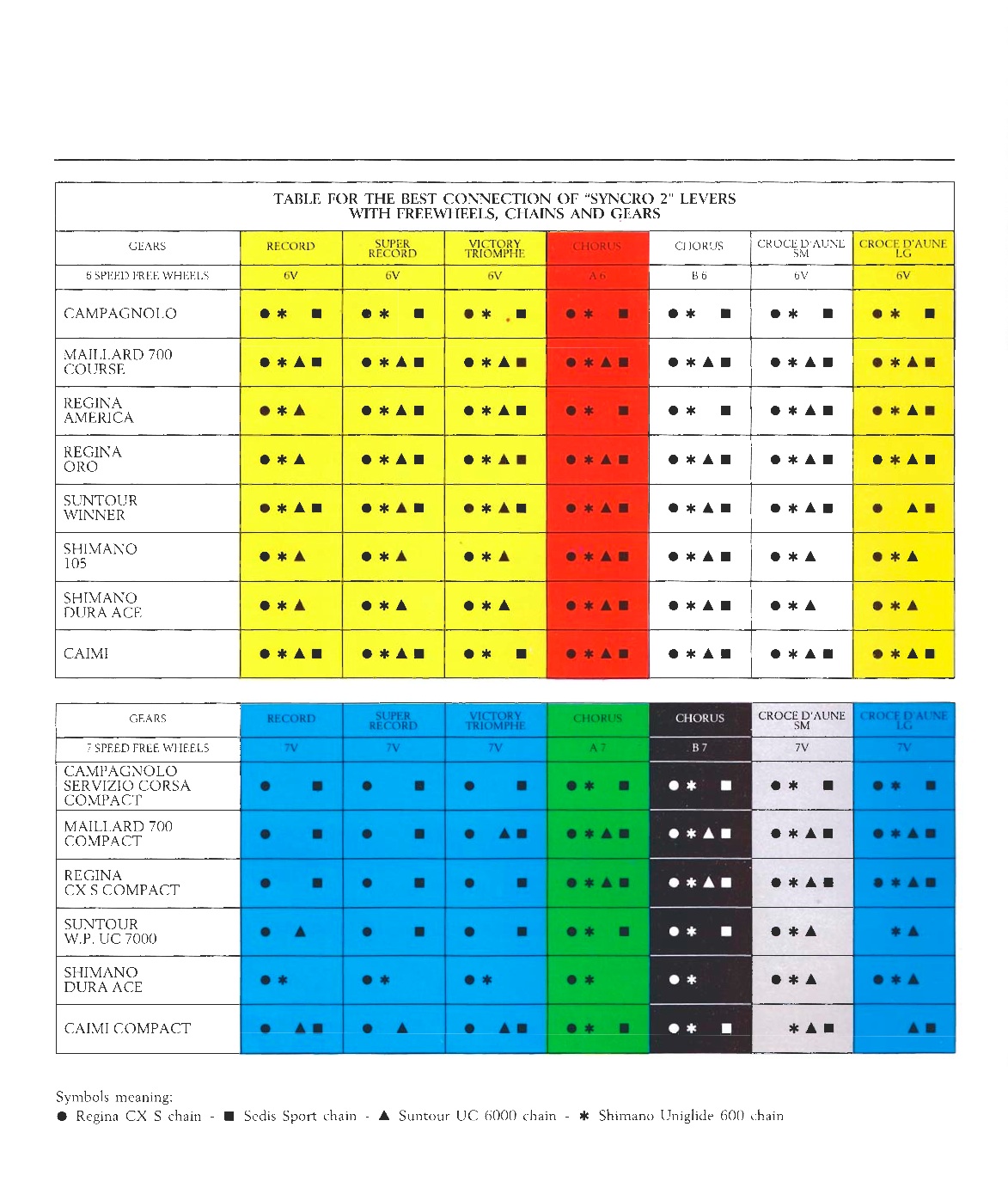

First things first. The first thing you MUST do is consult the tables provided by Campagnolo with regards to what combinations of freewheel, chain, dérailleur and shift collar work together. Yes -- the different colors of collars can be hard to find. In some ways, I'd suggest selecting your derailleur, freewheel and chain based on the collars you have access to. Some substitutions will work better than others, but unless you have lots of time and lots of spares, stick with something that Campy published as working. It can be hard enough setting up Syncro with the correct equipment.

One tip I read that seems to help comes courtesy of a usenet post by Andrew Muzi over at Yellow Jersey. He advocates artificially wearing the teeth of the shifter notched insert, using a buffing wheel. I used a dremel with a little bit of buffing compound, which also works. The goal is to take some of the square edges off the teeth of the collar. This eliminates some of the harsh edges you'll encounter when shifting, and make the whole system a little more tolerant of imperfect shifts. The above shows a slightly worn blue insert. Might be hard to see in the picture, but the tops of the notches begin to round slightly when they wear. The goal is to simulate repeated shifting, and eliminate any break in time for the shifter.

There are also some who advocate using a floating upper pulley -- similar to the kind you'd find in a modern derailleur. The bearing units tend to be more precise, and indexing systems can benefit from a little wobble as they're shifting. It provides a little overshift, to get the chain up on the next cog, and then lets it sort of float back to the appropriate location. Personally, I haven't had to resort to this, but it may make the system a little less finicky.

If your derailleur doesn't have a barrel adjuster, it should. Some Syncro shifter sets came with one, and once Syncro continued, derailleurs came with them. You need this for the fine-trim on your derailleur. The Campy supplied one is shown above, but you can cobble one together from your parts box.

One thing I've never read anywhere, but really seems to have a positive effect, is tightening the indexing lever more than you'd think. If you're used to modern indexing systems, you know the tension on the lever really has no impact on the quality of shifting. The tension isn't really all that adjustable. On the Syncro, however, having it snugged down further than you think seems to improve shifting accuracy immeasurably. If you hear a discreet 'click' when you shift, make them tighter! Mine make more of a thump sound when shifting...If you're used to friction levers, you will not end up tightening the indexing lever enough. Don't strip anything, but don't be shy either. I think this is related to the 2 springs not providing support for the insert when not tightened down (hence the eventual move to a much much better 3 spring version post-95). Just be careful -- I've seen cracked inserts before.

Use modern derailleur cables. They don't have as much stretch in them, and that seems to be a good thing. The use of linear cable housing may also be a wise thing, although I have to admit -- I'm using spiral housing successfully.

My setup works beautifully, if I do say so myself. I do *not* have to overshift, which was a common complaint with these. I think the wearing of the collar, in conjuction with the tight indexing lever makes all the difference. Curious about my setup? I use a Croce d'Aune derailleur, Regina Oro freewheel, CX chain and the yellow collar with Syncro 2 levers.

Here's a gratuitous picture -- a pile of NOS Syncro II's. Its all part of my effort to corner the market in obsolete, inferior technology.

9 comments:

Hey Jeremy,

Cool stuff :^) Thanks for sharing. I have two pairs of the end of the line C-Record retrofriction shifters, the ones with a huge cable barrel on for the rear dérailleur. I also have a complete, owned it since new Victory gruppo. Do you have any Syncro or Syncro II setups that would work with this dérailleur and a Sachs and/or Shimano 7 speed freewheel? Would you have any interest in some kind of trade? Not sure how these comments work or if you will ever see this...

Doug

P.S. 6 speed might be okay too, I had collected some 7S freewheels that I intended to use though...

Doug, if you ever read this, mail me at blogs at tears for gears dot com.

Thanks very much for your informative Syncro posts and pictures. I have a question on one of your tips. The old Campagnolo info sheet you linked to in one of your posts advises; "One last thing, remember never to overtighten the D-ring friction adjuster on the shift lever. Too much friction on the lever will not allow it center the derailleur under the freewheel cog after the shift has been made." This would seem to run counter to your own advice to tighten MORE than you think you should, in order to get best performance. I have noticed that LESS

tightening gives much more obvious "CLICK" behavior on my 1988 Syncro II levers, while more tightening of the lever gives much subtler feeling indexing. I wonder if the real difference in performance comes from how much manual trimming is being dialed in by the tightness setting. With less tight levers, the shifter finds and settles on the index point in the internal mechanism, giving an obvious CLICK, but little ability to subtly adjust slightly above or beyond this point manually (shifter always re-centers on the CLICK position. With tight levers, the shifter still indicates the index point by a slight "thump" feel, but the tighter shifter is also better able to hold any position yo set that is slightly above or beyond the precise index point. Do you think what you see as better performance with high tightness settings may be coming from whether the shifter can hold slight manual trim adjustments, or relies entirely on the centering points provided by the colored cogs?

Hi Jeremy,

Thanks for all the useful info in your various Syncro posts.

I'll concede you've pretty well cornered the market too :)

I have a set that I'd like to use on a classic steel framed machine (Mercian actually) but I have the B7 insert and I need the blue 7V insert to use with a Victory rear mechanism.

Would you be willing to supply me a 7V please? If so how much? I could part exchange the B7 if you want.

Thanks,

Henry

Hey I bought the syncro 2 shiters. I'm waiting for them to come with the mail soon. I also got a campagnolo record 1991 rear dellieur, but the barrel adjuster is missing.

The syncro 2 shifters are NOS (new old stock) should I expect the barrle adjuster in the box ?

And what if it's not. How do I get it ?

It's very small barrel adjuster hole. Probaly the smallest ever made.

Jeremy : thanks for your information. I'm agree with regarding the tightening of the levers. 1/4 turn of the scrfew make the difference!!

in my case i have a Campy Athena 91 derailleur, a regina Syncro 92 freewheel, a Shimano UG51 chain and Syncro2 levers with blue insert (Chain and levers are NOS).

At the begining I'd adjusted levers as usual and teh results were that I thougt why I spent my money in these levers, but after that unscrewing 1/4 turn results were excelent.(just like an 8 ergopowers levers)

thanks again!

So back to this old thread again! I just resolved my ill-shifting Croce system by jumping down to 6v. Evidently what I bought as the "white" 7v Croce ring must not have been. Now, I have Syncro shifting perfection! Love it!

Jeremy, I've come up with a modification of the Syncro mechanism I thought you might be interested in.

Like you, I bought a whole lot of syncro shifter parts and have since been working on putting them together.

The thing that always bothered me was the extent to which you had to tighten the D ring bolt in order to get accurate shifting like you describe in this post. The thumping index feel that results is unsatisfying, uncomfortably hard to move, and seems to me might as well be friction shifting. It does not feel easy and precise like the Suntour GPX indexed shifters or shimano index shifters that I was used to, and lacked a satisfying "click".

However, as you know, when the bolt is not so tight the shift lever has a significant amount of play, so much play in fact that it can even result in an unwanted downshift (at least in my experience). Imagining that I should be able to adjust the derailleur and freewheel to avoid this, it still leaves an uncomfortable amount of play in what is supposed to be "precise" index shifting.

So I modified my Syncro 2 to get rid of this play, which I found was caused by the difference between the gap in the notched collar and the second collar (that fits into the first) and the width of the two protruding teeth in the knurled springed collar piece. The lack of a snug fit of these two teeth into the corresponding gaps in the toothed and the other collar results in a play of about 10 to 20 degrees of the shift lever in each click of the indexing when it is not extra-tightened like you recommend. What I did was increase the width of the two teeth in the knurled collar piece by soldering some silver solder onto each tooth and then shaping it with a rotary to the proper shape. This meant that the teeth were now the exact size of the gap in the notched collar, and eliminated the play in the shifter entirely (without affecting the functionality of the index to friction switching).

Now I have accurate index shifting, a nice loud "click", and no irritating play in the shifter. Silver solder is softer than steel, so I will be trying a more durable iteration of this modification. I only wonder why Campangolo designed so much play in the index system, I can't see what possible purpose it can serve.

Hi,

I'm hoping you can help with some advice on how to get syncro 2 7spd levers coupled with a Maillard compact super 7spd freewheel, Rohloff 99 chain and 1990 record 8spd rear derailleur to work smoothly. This setup was apparently used by Greg Lemond during his 1990 TdF win. My assumption is that he used them indexed and not frictio so my preference is to try and make it work.

Thanks in advance

Brett

Post a Comment